Our Facilities

Outfitted for Operational Excellence

Cannara owns and operates two world-class facilities specifically designed to deliver premium cannabis products at some of the lowest cultivation costs in Canada.

oUR fACILITIES

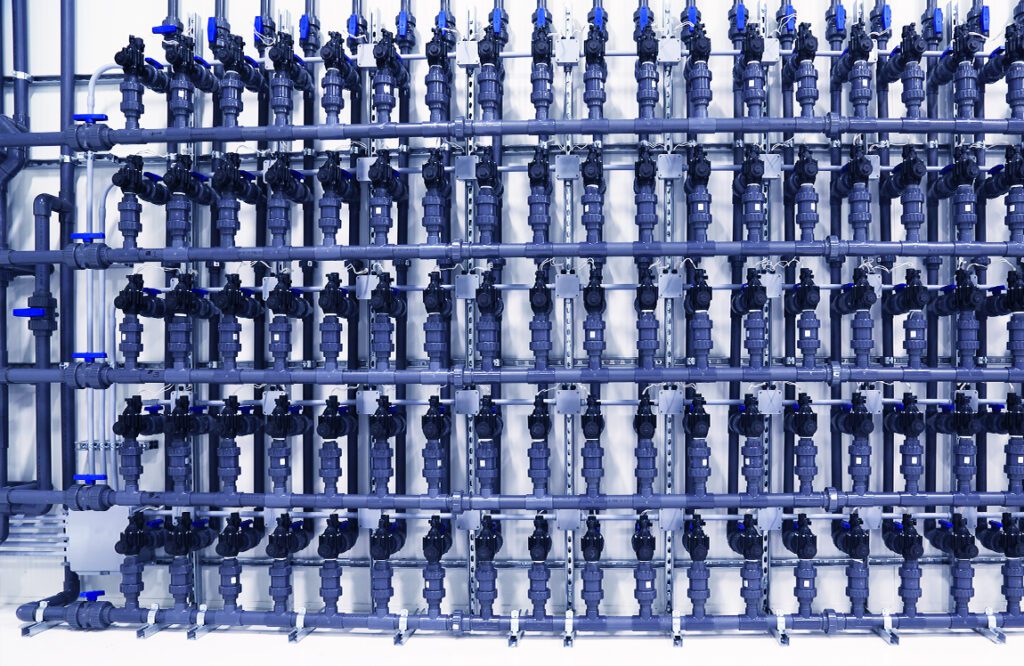

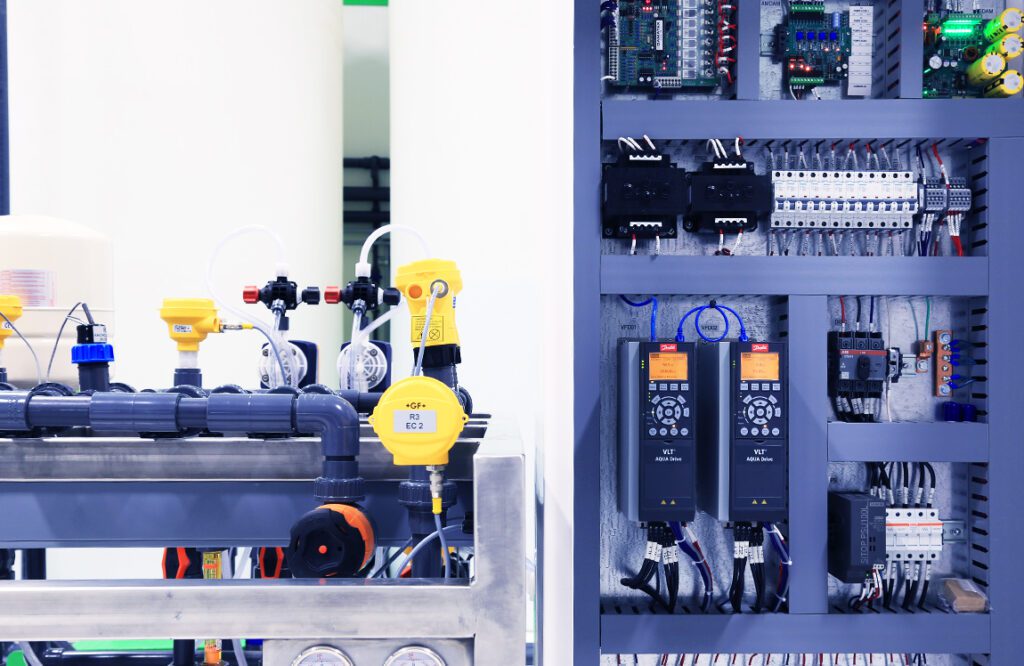

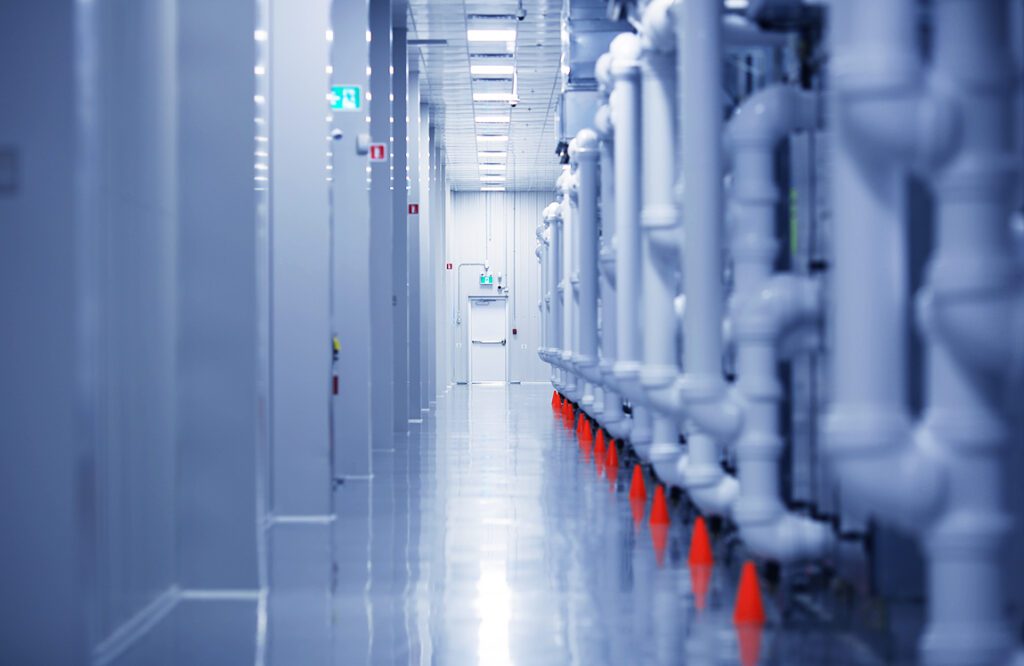

Cannara’s facilities span over 1 650 000 square feet providing up to 100 000 kg of annualized cultivation output. Built to deliver premium “AAAA” quality cannabis, our facilities are equipped with automated lighting, irrigation, humidity and biomonitoring controls to ensure quality, consistency, increased plant yield, and reduced operating and cultivation costs. Our facilities are fully outfitted for operational excellence.

FARNHAM

Quebec's largest indoor facility

Cannara has built one of the largest indoor cannabis cultivation facilities in Canada and the largest in Quebec. Located in Farnham, this facility was built in just 14 months, and spreads over 27 acres with a total building size of 625,000 square feet. Farnham’s first phase of operation is sized at 170,000 square feet with a growing capacity of up to 3,500 kg per annum. This facility integrates onsite cultivation, extraction, processing and final packaging.

| Asset: | Farnham Facility |

| Location: | 1144 Boulevard Magenta E, Farnham, Quebec, J2N 1C1 45 minutes from Montreal. |

| Size: | Grow: 170,000 sq. ft. Site: 625,000 sq. ft. Land: 1,430,000 sq. ft. |

| Type: | Indoor cultivation. |

| Year Built: | Phase 1 completed in 2019 |

| Capacity: | 11 independent grow rooms 3,500 Kg per year in phase 1 |

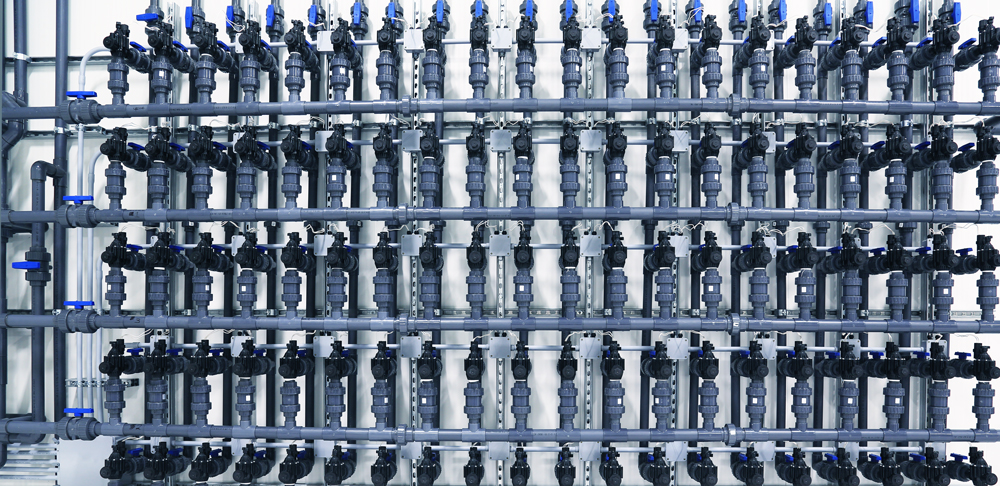

Asset Highlights: Our Farnham facility is fully automated and equipped with nutrient delivery and irrigation, HPS lighting, climate and temperature control, dehumidification, and biomonitoring sensors in every grow room to ensure total control over and optimal cultivation conditions.

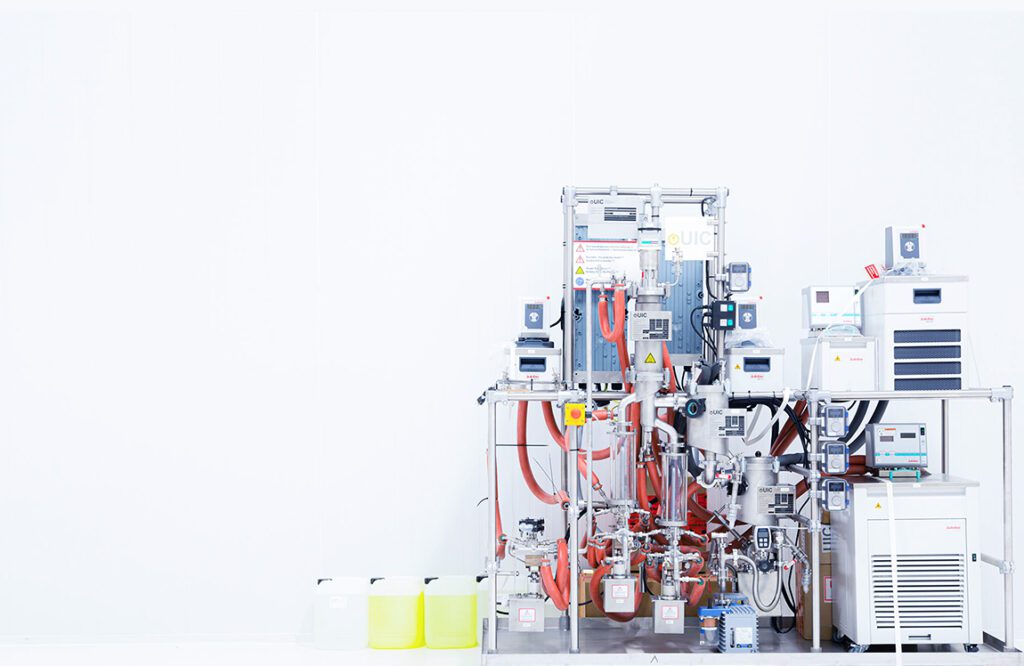

Asset Highlights: Our Valleyfield facility includes automated systems for nutrient delivery and irrigation, LED lighting, climate and temperature control, misting, dehumidification, state-of-the-art table growing system, blackout and shading curtains, and smart tempered glass roofing. In addition to this, the air exchange, filtration, and water systems operate on closed loops to reduce waste and costs.

Valleyfield

indoor growing at another level

Located in Valleyfield, Quebec, the newly-built facility occupies 1,030,000 square feet on 3,000,000 square feet of land and provides up to 96,500 Kg of output at full capacity. This completely automated facility is equipped with cutting edge technology including irrigation, robotics, lighting, automatic shading and smart tempered glass roofing, capable of achieving growing conditions found in our Farnham indoor facility.

| Asset: | Valleyfield Facility |

| Location: | 1175 Boulevard Gérard-Cadieux, Salaberry-de-Valleyfield, Quebec, J6T 6L3 50 minutes from Montreal. |

| Size: | Grow: 600,000 sq. ft. Site: 1,033,506 sq. ft. Land: 3,131,000 sq. ft. |

| Type: | Hybrid indoor/greenhouse cultivation. |

| Year Built: | 2020 |

| Capacity: | 24 independent grow rooms Up to 96,500 Kg per year |

We've Got Control

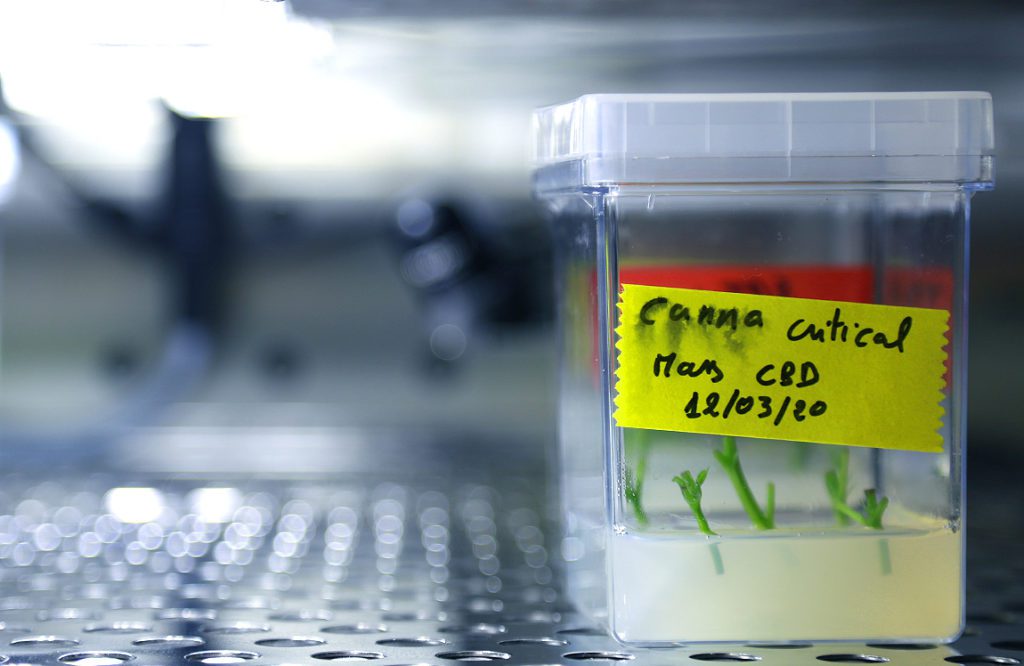

Producing great cannabis is all about control. That’s why we’ve gone through uncompromising efforts to deliver two best-in-class facilities that allow us to isolate and optimize every element of the cultivation process. As each and every cannabis genetic requires precise fine-tuning at each stage of its growth cycle, each and every one of our “gardens” can be controlled and optimized throughout our facilities in order to recreate the natural environments in which cannabis plants thrive. Take a look at what makes our facilities produce premium cannabis flower:

Temperature

Using gold-standard HVAC technology, we’re able to closely monitor and adjust temperature on a room-by-room basis. This allows us to ensure that every plant is comfortable in its environment throughout every stage of its growth.

Humidity

Lighting

For plants, light is everything. We’ve invested in world-class lighting, including different systems for each stage in the plant’s lifecycle – from clone, to mother, to vegetation, to flowering, every stage has exactly what it needs.

Irrigation

Nutrients